BLOG POST #9

Vertical Integration

As one can imagine, businesses and companies are consistently always looking for new methods and strategies to reduce costs and manage the quality of the products and services they offer. It really comes down to doing whatever is necessary to gain a competitive advantage against the competition in the hopes of being able to benefit in one way or more. One way that a company can generate a competitive advantage is by incorporating different stages of its production process and supply chain into their business, this is called vertical integration.

What is it?

Vertical integration is the strategy that allows a company to streamline its operations by taking direct ownership of numerous stages of its production process rather than depending on outside contractors or suppliers. In other words, a company or business takes control of two or more of the steps involved in the making and selling of their product or service. They do this because it makes their organization and systems more efficient and reduces late deliveries. For instance, a business may find itself too reliant on another for its supplies and this other business may be unreliable. By vertically integrating, the supplier no longer has to worry about customers and the buyer no longer has to worry about late and unreliable deliveries.

Its Affect on Society

Vertical integration has a positive affect on society. It gives a company or business a better economies of scale such as producing more products at lower prices. This allows for an increase in a business's supply, lowers the fixed variable costs per unit, and makes the product more attractive to the consumers.

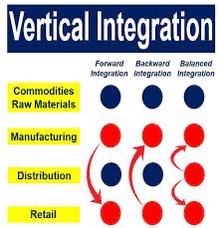

Three Types of Vertical Integration

Forward Integration

Also known as upstream integration. This is where a company acquires or expands with another that is ahead of it in supply. In other words, it is where a company essentially mergers or buys its customer. This is a fairly uncommon practice because the companies at the end of the supply chain are very condensed.

Backward Integration

Also known as downstream integration. This is where a company joins with another that is at a stage before itself in the supply chain. In other words, it is where a company integrates with one of its suppliers. This type of vertical integration is fairly common because big businesses at the end of the supply chain tend to be able to have purchasing power to consume their suppliers.

Also known as upstream integration. This is where a company acquires or expands with another that is ahead of it in supply. In other words, it is where a company essentially mergers or buys its customer. This is a fairly uncommon practice because the companies at the end of the supply chain are very condensed.

📦 → 🏭 → 🚛 → 🏠

Supplier Manufacturer Distributer Retailer

Backward Integration

Also known as downstream integration. This is where a company joins with another that is at a stage before itself in the supply chain. In other words, it is where a company integrates with one of its suppliers. This type of vertical integration is fairly common because big businesses at the end of the supply chain tend to be able to have purchasing power to consume their suppliers.

📦 ← 🏭 ← 🚛 ← 🏠 ------- Supplier Manufacturer Distributer Retailer

This is the third type of vertical integration and it is a combination of both forward and backward integration. This is where a company merges with both a company that is before it in the supply chain as well as one that is after. In other words, it involves two transactions, one being the supplier to provide raw materials and the second being the distributer to sell its products. This is a fairly rare type of integration because of the cost and potential legal disputes that may surface due to monopoly control of the vertical supply chain.

Some Advantages of Vertical Integration

- Lower transportation costs and turnaround times

- Improved profitability

- No reliance on suppliers

- Economies of scale (lower costs)

- Reduced disruptions and quality problems from suppliers (since it controls its own supply chain, it is better able to control and deal with any supply problems itself)

Some Disadvantages of Vertical Integration

- Reduces flexibility (are now forced to follow trends in the segments they integrated)

- Initial costs are significant (companies must invest great deals of money to set up and buy factories)

- A company may underestimate the difficulty and cost of the overall process

- Outsourcing to a company with superior expertise may be a better choice

- Unforeseen labor issues

Companies that exercise vertical integration...

In the 19th century, this used to be a massive steel manufacturer. They used vertical integration by acquiring companies before itself in the supply chain. The process to make steel required the certain raw material extractions of iron and coal. Then, those raw materials needed to be refined before they could be manufactured into the final product. Carnegie Steel owned both the miners that extracted the raw materials, as well as the refineries.

Amazon

This is the world's largest online retailer that sells books, housewares, music, movies, toys, electronics, and many other goods. Today, Amazon has vertically integrated most of its business. It acts as a marketplace for buyers and sellers, as well as offers its own products and services and distribution channel. In other words, it has the three stages in its supply chain.

This is the world's leading smart phone maker. This company uses backward integration by manufacturing the chipset used in their popular devices. By using this method, they have been able to keep a check on quality and budget its cost of chipsets. So, providing quality at better prices. Apple has also used forward integration by opening its retail stores to sell their entire product line. This allows them to save on commissions that would be paid to retail partners.

This is a Spanish clothing and accessory company that has a thousand stores worldwide. Zara is vertically integrated with both the manufacturers and designs of its goods. They not only own their own retail stores and distribution, but also the majority of their clothes are sourced inhouse. Due to this strategy, Zara is able to easily adapt to trends much quicker than its competitors as well as improve their stock management efficiency.

This is a famous global fast food chain. This business practices backward integration by setting up its own manufacturing plants to produce the raw materials which are used for the preparation of their burgers, fries, ice cream, and beverages. They also raise their own agricultural products to maintain quality and ensure the same products are offered worldwide in their stores.

Comments

Post a Comment